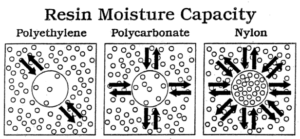

Let’s understand why materials need to be dried in the first place. For thermoplastics, there are hygroscopic and non-hygroscopic resins. Hygroscopic resins have an affinity for moisture, and it gets absorbed into the polymer chains of the material. For hygroscopic resins (polymers that naturally absorb moisture such as Nylon, PBT, PET, ABS, and PC products), it is critical to ensure proper drying of the material prior to processing it. In doing so, you will help prevent part failure due to hydrolysis and cosmetic defects such as splay or silver streaking. Hydrolysis is the chemical breakdown of a compound due to the reaction caused by the presence of moisture in elevated temperatures. This means that when a hygroscopic resin is processed with moisture, it causes the polymer chains to break, resulting in a significant decrease in mechanical properties.

Below is an example of the resin moisture capacity of 3 polymers; polyethylene (non-hygroscopic), polycarbonate (hygroscopic), and nylon (hygroscopic). Every polymer has its own capacity to absorb water, meaning some will absorb water more readily than others.

When molding hygroscopic materials, it’s recommended to use a desiccant dehumidifying style dryer to properly remove moisture from the material. Let’s understand how a desiccant dehumidifying style dryer works:

- It dries the air to the required dew point level

- Heats the air to a specified temperature

- Circulates the heated airflow within its own closed-loop system

- Moisture migrates out of the polymer and is removed from the circulating air via desiccant bed

The desiccant bed is a cartridge type “filter” made up of moisture-absorbing desiccant beads. An example of this would be the silica gel desiccant beads found in everyday consumer items/packaging (i.e., dry goods, shoe boxes, vitamin containers, clothing, and packaging). The silica gel desiccant beads act as a dryer and capture unwanted moisture, preserving the product.

Now let’s review dryer maintenance and how you can tell if your desiccant beads are bad. This is important to understand, so you aren’t molding material that still has moisture in it when processing. As mentioned previously, processing hygroscopic materials with moisture leads to cosmetic defects and hydrolysis, which breaks the polymer chains affecting the overall mechanical properties of the material/ part.

There are three ways to tell a desiccant is bad in your dryer:

- You cannot hold the desired set dew point on your dryer for the material. If it never reaches the desired dew point or doesn’t hold it for long, then it’s probably time to change the desiccant.

- Pull the desiccant beads out and squish them between your fingers. If they are very brittle and crumble upon doing so, they’re bad and need to be replaced.

- Take a styrofoam cup, fill it with about 1 inch of desiccant beads, and pour water on them, just enough to cover them or leave a few above the water. It’s good to know what the water temperature is before filling the cup. If the cup and water get hot, then they’re still good. However, if it remains cold, then it’s time to change the desiccants. When desiccants absorb moisture, they give off heat. You can then use a thermometer to measure the water temperature difference after the water reacts with the desiccant beads to see the change in temperature.

Written by:

The Chase Plastics team of engineers is ready to assist with any drying and process related questions you may have. Give us a call at 844-411-2427 or send an email at engineering@chaseplastics.com to get support on any of your technical needs today!

If you have questions on the topic above or have another issue to tackle, please submit your inquiry in the questions/contact form. Someone from our technical team will be in touch once it has been submitted.