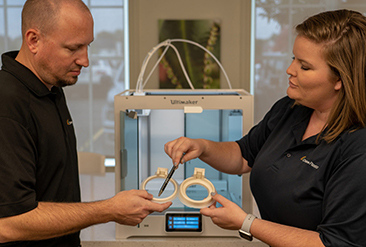

3D printing helps manufacturers reduce time and costs while increasing efficiency. Chase Plastics will help you navigate the process of additive manufacturing with the tools, resources and suppliers to help you thrive. As a stocking distributor with several options, our trusted experts simplify and guide you through the most complex 3D printing material selection processes to provide more design freedom and efficiency at your target cost.

Need help? Contact Us

Need technical assistance? Contact our engineering help center: 844-411-CHASE (844-411-2427) or engineering@chaseplastics.com or complete the form here.