Chase Plastic Services, Inc., a leading distributor of specialty, engineering, and commodity thermoplastics, announced today that it obtained the International Sustainability & Carbon PLUS (ISCC PLUS) certification demonstrating environmental and sustainability compliance within its supply chain. The certification marks a significant milestone in the company’s ongoing commitment to sustainability, enabling Chase Plastics to offer ISCC PLUS-certified products in partnership with trusted, certified suppliers.

The addition of ISCC PLUS-certified materials to its already extensive product line makes Chase Plastics even better positioned to offer customers sustainable and traceable plastic products. The ISCC PLUS certification provides traceability along the supply chain and verifies that the material distributed meets various sustainability requirements.

“Our ISCC PLUS certification is a step forward in our mission to provide customers with high-quality materials while prioritizing environmental responsibility,” said Adam Paulson, President of Chase Plastics. “This addition allows us to deliver our suppliers’ certified sustainable thermoplastics, traceable through the entire supply chain, to our valued customers and brand owners.”

Chase Plastics remains dedicated to helping customers make informed choices in materials that align with their values. Through its network of suppliers, Chase Plastics offers solutions that meet both performance standards and sustainability objectives, supporting a more responsible future in the plastics industry.

About Chase Plastics

Chase Plastic Services, Inc., is a stocking distributor with a portfolio that offers more than 35,000 varieties of specialty, engineering, and commodity thermoplastics from the industry’s leading manufacturers and global suppliers. As a top-ten North American specialty and engineering plastics distributor, Chase Plastics is committed to helping their customers turn resin into reality by Redefining Resin Distribution.®

The Company, formed in 1992, provides customers with an industry-leading portfolio of value-added services delivered by skilled sales professionals and dedicated teams of technical process engineers, market development engineers, and more – all of whom guide the material selection, application development, and manufacturing processes. The Company’s unmatched level of dedicated support, together with blending, repacking, inventory management, and logistics services via a network of distribution and sales locations throughout North America, is singularly focused on helping customers boost efficiencies and profitability.

Based in Clarkston, Michigan, Chase Plastics was founded by Kevin and Carole Chase, who serve as the Company’s CEO and Vice President, respectively. Learn more about Chase Plastics and its commitment to providing outrageous customer service at https://chaseplastics.com/

Posted by

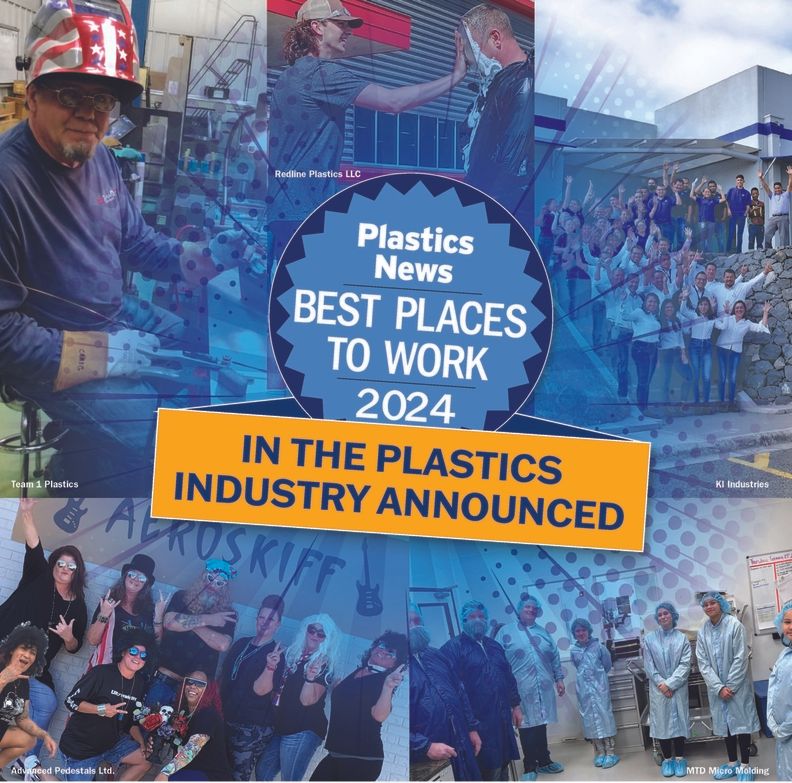

Sixteen companies have been named a Best Place to Work in the plastics industry for 2024.

Sixteen companies have been named a Best Place to Work in the plastics industry for 2024. Clarkston, Mich. — Chase Plastics announced today that they are an authorized distributor for the new global engineering materials entity, Envalior. Formed last year, Envalior brings together two established global material players − DSM Engineering Materials and LANXESS High Performance Materials − and a combined heritage of over 100 years.

Clarkston, Mich. — Chase Plastics announced today that they are an authorized distributor for the new global engineering materials entity, Envalior. Formed last year, Envalior brings together two established global material players − DSM Engineering Materials and LANXESS High Performance Materials − and a combined heritage of over 100 years. Chase Plastics and an executive from Wittmann USA are doing their part to make holidays brighter for those in need.

Chase Plastics and an executive from Wittmann USA are doing their part to make holidays brighter for those in need.

MESSAGE FROM THE PRESIDENT

MESSAGE FROM THE PRESIDENT Plastics News

Plastics News