Consumers of plastic products want to feel positive and know they are doing something good for the earth and its inhabitants by buying “green” or sustainable products. Consumers demand products that will lower our reliance on fossil fuels and decrease greenhouse gas emissions. Plastic product manufacturers and brand owners are also looking for ways to reduce their carbon footprint. How do we accomplish this? Sustainable materials.

To understand our options for sustainability in the plastics industry, we must first understand some key terms or buzz words surrounding these materials:

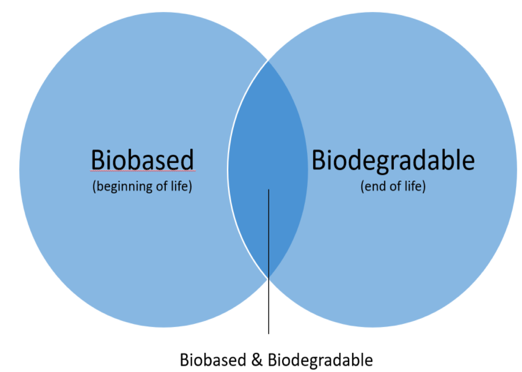

- Bioplastics: a family of materials that can further be split into two groups: biobased and biodegradable.

- Biobased: (beginning of life) These materials are made entirely or partially from bio/renewable carbons (plant-based) compared to standard petroleum/fossil fuel-based carbons.

- Biodegradable: (end of life) These materials can undergo biodegradation, a chemical process in which microorganisms convert the materials into natural substances like water, carbon dioxide, and compost.

- Compostable: Materials that have been tested and certified by a third party to adhere to international standards such as ASTM D6400 (in the U.S.) or EN 13432 (in Europe) for biodegradation in an industrial composting facility environment.

- Biocomposite: combines traditional plastics with biomaterials like wood, flax, hemp, starch, etc., to be used as filler or reinforcement.

Bioplastics can be either 1) non-biodegradable and fully or partially biobased, 2) biodegradable and fully petroleum-based, or

3) biodegradable and fully or partially biobased.

Now that we understand what the key terms are for bioplastics, what type of practical options are there for approaches to sustainability with plastic products?

- Renewable feedstocks: Utilization of biobased plastics and biocomposites from starch and other natural fiber feedstocks reduce the amount of greenhouse gas emissions associated with traditional plastic production.

- Reclaimed feedstocks: Utilization of other industry’s byproducts to create biocomposites (think wood fiber millings) to replace petroleum-based feedstocks in traditional plastics can also reduce the amount of greenhouse gas emissions.

- Biodegradable materials: Biodegradable & compostable plastics can help reduce landfill waste, mainly when used for food service in conjunction with composting of food waste and in many packaging applications.

- Recycled materials: Opting for recycled plastic over virgin-based plastic feedstock yields tremendous energy savings. It also gives the material a second life (think carpet fibers being reprocessed into post-consumer polyamide grades or scrap parts being reprocessed into post-industrial grades of various materials).

Equipped with understanding the key terms for bioplastics and practical approaches, processors and brand owners can opt for “greener” options that satisfy consumers’ needs for a more sustainable product.

The Engineering Team here at Chase Plastics is ready and willing to walk you through any analysis needed to offer suitable electrostatic dissipative materials to meet your needs. Give us a call at 844-411-2427 or send an email to engineering@chaseplastics.com to get support on any of your technical questions today!

If you have questions on the topic above or another issue to tackle, please submit your inquiry in the questions/contact form to the right. Someone from our Technical Team will be in touch within 2 hours!